Technology

A new paradigm

Our technologies enable better motors to be designed and built faster.

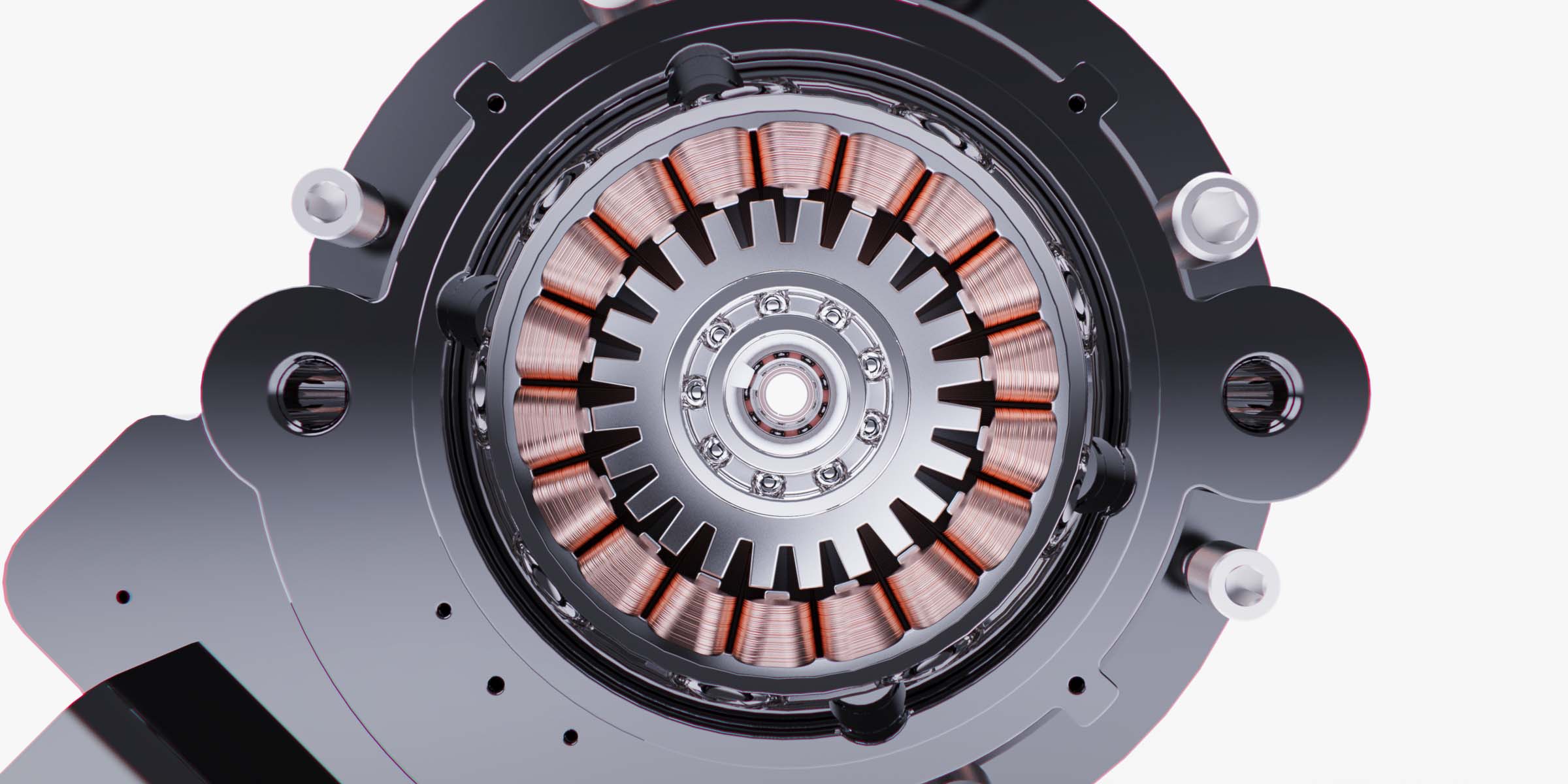

IMPROVED MOTORS + POWER ELECTRONICS

Reduce + Eliminate

Permanent Magnets

Every day, millions of electric motors are manufactured. A significant number them, particularly for propulsion systems, use rare earth metals in permanent magnets. These magnets often represent 40% or more of the total cost of a propulsion motor.

Enedym takes the need for rare earth metals completely out of the electric motor equation. Our novel SRMs (switched reluctance motors) do not contain rare-earth metals. Our designs for IPMSMs (interior permanent magnet synchronous motors) reduce rare-earth content.

- High efficiency at high speed

- More reliable

- Fault tolerant operation

- Advanced acoustic noise control

- High performance in harsh conditions

- More stable supply chain

ADVANCED DESIGN ENVIRONMENT

System design

at a fraction of time + cost

Today’s design and validation processes for electric propulsion systems aren’t fast enough. Gaps in knowledge, capacity, and technology mean high cost and slow development cycles.

Enedym has digitized design + development of electrified powertrains and electric propulsion units. With our unique software platform, Enedym can accelerate any design, exploration, experimentation, and development strategy.

- Powertrain System Analysis + Comparison

- Component Sizing

- Controls Development

- Requirements Commonization

HIGH-SPEED PROTOTYPING

Accelerated manufacturing development

The iterative process of going from prototype to volume production typically requires massive investment of time, expertise, and capital.

Enedym has developed resources and partnerships that greatly speed the process of design exploration and validation and optimization for volume production, shortening the process from years to weeks, and months to days.

- Rapid Fabrication of Prototypes

- Sample Comparison and Validation

- Volume Manufacturing Planning + Integration

Deep Expertise

We are a technology company

We have ownership of over 50 patents and pending patent applications and related inventions developed by the Canada Excellence Research Chair in Hybrid Powertrain Dr. Ali Emadi and his research group at the McMaster Automotive Resource Centre (MARC), McMaster University.

As one of the largest research groups in transportation electrification technology in academia in North America, Enedym is the result of 7 years of intense research and development at MARC.